Specification

Chemical Properties of Acrylic Sheet

| Resiatant Properties to Chemical Agents | |

|---|---|

| Sufuric Acid 60oC | stability to 60 % |

| Hydrochloric Acid 60oC | stability to 30 % |

| Nitric Acid 60oC | stability to 20 % |

| Caustic Soda 60oC | stability to 50 % |

| Aqueous Ammonia 60oC | stability to 18 % |

| Acetic Acid 60oC | dissolvable |

| Chlorine Water | change to dark color |

| Iodine Tincture | easily colorate |

Resistant Properties to the Solvents

- Corrosion resistant at room temperature :

- haxane, octane, formaldehyde 40% , methanol, ethanol, glycol, petroleum ( contained a little aromatic groups )

- Expansion of track at room temperature :

- chioroform, benzene, toluene, xylene, acetylene dichloride, acetone, ethyl acetate.

Physical Properties of Acrylic Sheet

| Specific gravity | 1.19 |

| Hardness | M-100 |

| Absorptivity of water (24hr) | 0.3% |

| Tension | |

|---|---|

| Coefficient of rupture | 700kg/cm2 |

| Coefficient of elasticity | 28,000kg/cm2 |

| Bending | |

|---|---|

| coefficient of rupture | 1.5kg/cm2 |

| coefficient of elasticity | 28,000kg/cm2 |

| Transmittancy (parallel rays) | 92% |

| (full rays) | 93% |

| Heat distortion temperature | 100oC |

| Coefficient of linear expansion | 6x10 -5cm/cmoC |

| Ultimate temperature of continuous operation | 80oC |

| Thermoforming ranges | 140-180oC |

| Insulating Strength | 20v/mm |

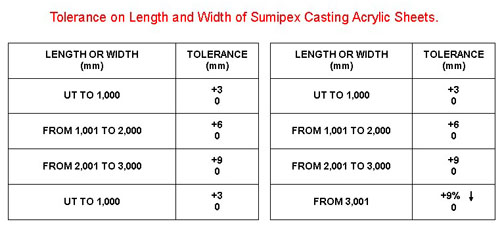

Tolerance on Length and Width of Sumipex Casting Acrylic Sheets

CLASSIFICATION OF DEFECTS

| CLASSIFICATION | SURFACE DEFECTS | INCLUSION DEFECTS |

|---|---|---|

| NEGLIGIBLE | LESS THAN 1 mm2 | LESS THAN 1mm2 |

| ACCEPTABLE | 1 TO 3 mm2 | 1 TO 3 mm2 |

Pay more attention to the usage of acrylic sheets

-

Temperature :

Acrylic sheets are softened with heating at 100ºC Centigrade or over. To prevent from becoming soft, please keep units beyond the place over 100ºC Centigrade. -

Scratch :

The hardness of surface is equivalent to aluminum, thus be careful to surface protection during process. If there are scratches on the surface of acrylic sheets, polish them with cleaner used for brass that can remove its brilliant surface. -

Cleaning :

Due to acrylic sheet with static electricity, clean the surface with soft and dry cloth wetted 1% soap water when there is dust on the surface. -

Swell :

The coefficient o heat is larger and its tension is about nine times of other metal materials. Remain enough space for its contractility to variable temperature while you install and fix acrylic sheets steady.

Special Instruction Under Installation

Reserve enough space for contractility, the elasticity of cast acrylic sheet per meter is as following, according to the temperature.

(A) After finishing processed acrylic novelties at 10 Centigrade, the temperature raises to 50°C 1000 x 8 x 105 x (50-10) = 3.2m/m (elongation)

(B) After finishing processed acrylic novelties at 10 Centigrade, the temperature falls to -10°C 1000 x 6 x 105 x (30+10) = 2.4m/m (shrinkage)

You can consult general settlements to prevent from troubles as following :

- Reserve the frame for contractility.

- Making elliptical hole with screw.

- Cushion material as elastic as rubber

- Making acrylic novelties into unprominent shape.

- Using form to increase the cross-sectional coefficient avoiding interior stress.

Prevent Transformation

- Forming acrylic sheets into wave, wrap and through to increase cross-sectional coefficient in order to prevent trans formation from the weight of acrylic sheet itself and lasing.

- Increasing thickness of acrylic sheet as larger length and dimension.

- Counting thickness, tension tolerance and bending strength of acrylic sheet to endure wind pressure on the surface.